Octagonal Ring Joint Gasket: Enhancing Sealing Performance in High-Pressure Applications

2023-10-17

Introduction:

In industries that deal with high-pressure environments, ensuring reliable sealing is of paramount importance. The octagonal ring joint gasket has emerged as a trusted solution for sealing applications in challenging conditions. In this blog, we will explore the features, benefits, and applications of the octagonal ring joint gasket, highlighting its role in enhancing sealing performance and maintaining the integrity of critical systems.

1. Understanding the Octagonal Ring Joint Gasket:

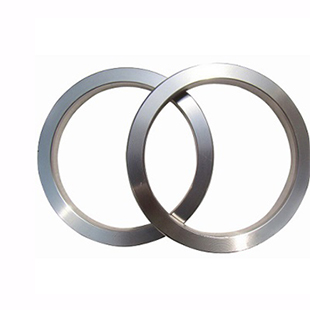

The octagonal ring joint gasket is a metallic sealing gasket that is commonly used in high-pressure and high-temperature applications. It is typically made from materials such as soft iron, stainless steel, or carbon steel, which provide excellent mechanical strength and resistance to corrosion.

2. Unique Octagonal Design:

The name "octagonal" refers to the gasket's shape, which features eight sides. This design allows for greater contact area and sealing surface, ensuring a more effective seal. The octagonal shape provides improved sealing performance and stability under extreme pressure and temperature conditions.

3. Sealing Integrity in High-Pressure Environments:

Octagonal ring joint gaskets are specifically designed to withstand extreme pressures, making them ideal for sealing applications in industries such as oil and gas, petrochemical, and power generation. The gasket's robust design enables it to maintain a reliable seal even under immense pressure, preventing leaks and ensuring the integrity of critical systems.

4. Adaptability to Flange Surfaces:

Octagonal ring joint gaskets are designed to fit specific flange surfaces, such as those conforming to API standards. They are commonly used in conjunction with ring-type joint (RTJ) flanges, which feature grooves where the gasket sits, ensuring proper alignment and sealing. This adaptability allows for consistent and secure sealing in a variety of flange configurations.

5. Resistance to Extreme Temperatures:

Octagonal ring joint gaskets exhibit excellent resistance to high temperatures, making them suitable for applications that involve extreme heat. They can withstand temperatures ranging from cryogenic conditions to elevated temperatures, ensuring sealing integrity even in challenging environments.

6. Reliability and Longevity:

The robust construction and high-quality materials used in octagonal ring joint gaskets contribute to their durability and longevity. These gaskets are designed to withstand repeated use and maintain their sealing properties over an extended period, minimizing the need for frequent replacements and reducing downtime.

7. Compliance with Industry Standards:

Octagonal ring joint gaskets are manufactured to meet industry standards, such as the American Petroleum Institute (API) standards for gaskets and flanges. This ensures compatibility and interchangeability with other components within the system, allowing for easy installation and maintenance.

Conclusion:

The octagonal ring joint gasket is a reliable sealing solution designed to withstand high pressures and extreme temperatures. With its unique octagonal design, adaptability to flange surfaces, and resistance to challenging conditions, this gasket enhances sealing performance and maintains the integrity of critical systems in industries where sealing reliability is paramount. Consider the octagonal ring joint gasket for your high-pressure applications, ensuring secure and leak-free sealing while ensuring the safety and efficiency of your operations.