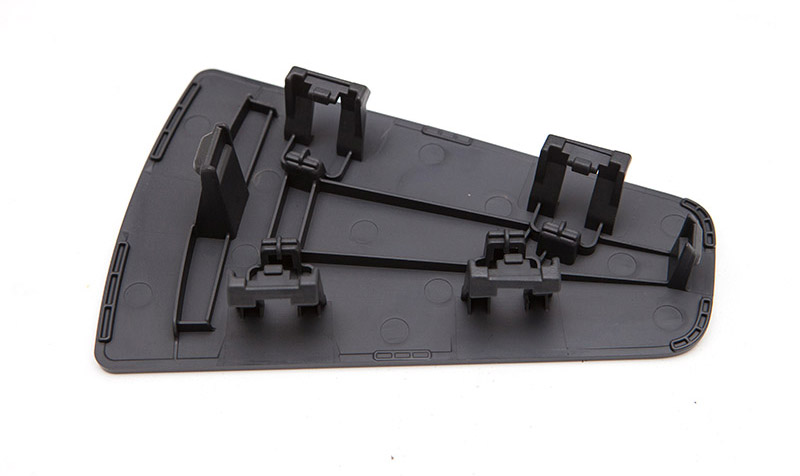

Shell of Gas Cutting Machine

A gas cutting machine typically consists of several components, including a shell or housing that encloses the various parts and provides protection. The shell of a gas cutting machine is designed to contain the internal components, ensure operator safety, and provide structural support.The shell is......

Send Inquiry

Product Description

A gas cutting machine typically consists of several components, including a shell or housing that encloses the various parts and provides protection. The shell of a gas cutting machine is designed to contain the internal components, ensure operator safety, and provide structural support.

The shell is usually made of durable materials such as steel or aluminum to withstand the heat, sparks, and mechanical stresses associated with the cutting process. It is designed to be sturdy and rigid, offering stability during operation. The shell of a gas cutting machine may have various features depending on the specific model and manufacturer. Some common elements include:

1. Control Panel: The front or top section of the shell often houses the control panel, which allows operators to set parameters such as cutting speed, gas flow rate, and ignition controls.

2. Torch Mounting: The shell typically has a designated area where the cutting torch is mounted. This can be a fixed mount or a movable mechanism that allows for adjusting the torch position.

3. Gas Supply Connections: The shell incorporates gas supply connections, usually located on the rear or side, to allow for the input of fuel gases (such as acetylene, propane, or natural gas) and oxygen.

4. Cooling System: In some advanced gas cutting machines, the shell may include provisions for cooling systems, such as fans or vents, to dissipate heat generated during operation and prevent overheating.

5. Safety Features: The shell may have safety features such as interlocks, emergency stop buttons, or protective barriers to ensure operator safety and prevent accidents.

6. Viewing Windows: Gas cutting machines often have transparent viewing windows on the front or sides of the shell. These windows allow the operator to monitor the cutting process and observe the workpiece.

It's important to note that the specific design and features of the shell may vary between different models and manufacturers of gas cutting machines.