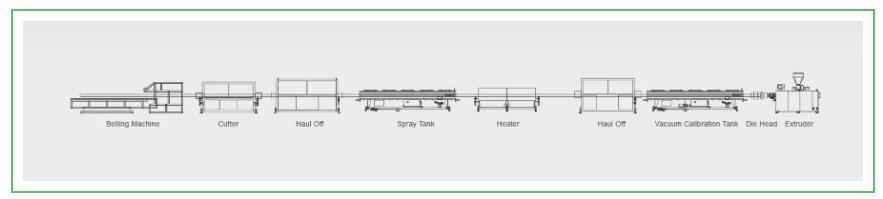

PVC-O UPVC Pipe Making Machine Line

PVC-O UPVC pipe making machine line is composed of a conical twin-screw extruder, mould, vacuum calibration tank, haul-off, cutter, staker, etc.The extruder and haul-off adopt imported AC frequency control devices, and the vacuum pump and haul-off motors adopt high-quality brands.The haul-off method......

Send Inquiry

Product Description

PVC-O UPVC pipe making machine line is composed of a conical twin-screw extruder, mould, vacuum calibration tank, haul-off, cutter, staker, etc.The extruder and haul-off adopt imported AC frequency control devices, and the vacuum pump and haul-off motors adopt high-quality brands.

The haul-off methods are two-claw, three-claw, four-claw, six-claw, eight-claw, etc. You may choose the saw-cutting type or the planetary-cutting type.

The pipe extrusion machine is additionally attached to the length counter and intensifying device.

The pipe extrusion equipment has reliable performance and high production efficiency.

COST EFFICIENCY

half the thickness of PVC-U pipe. Raw materials are cost-effective.

4 Times impact resistance to external loads

ENERGY EFFICIENT

Smooth inner wall.

Higher water conveyance.

Increased hydraulic capacity

Between 15 and 40% more hydraulic capacity than PVC-U or HDPE.

OPTIMAL ENVIRONMENTAL PERFORMANCE

Optimal environmental performance

Energy efficient